Ideal Industries Casting Division

Manufacturer of Graded Grey & Ductile Iron Castings

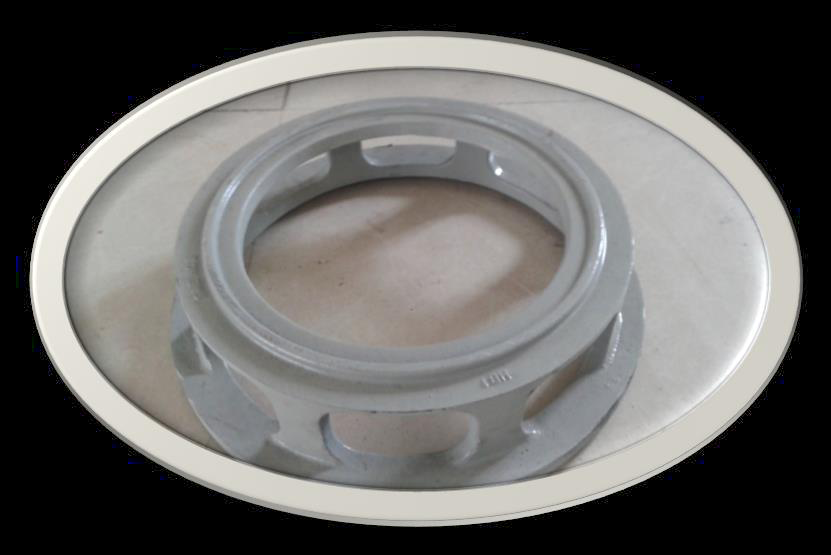

Products manufactured by Ideal Industries Casting Division are

- Clutch Housing

- Balancer Shaft

- Bearing Cartridge & Cap

- End Shield & Stator Case

- Valve Bodies

- Rotor

- Compressor Casting

- Strainer Body & Cover

- Wheel Support

- Guide Plate

- Bonnet Casting

- Axle Housing

Infrastructure

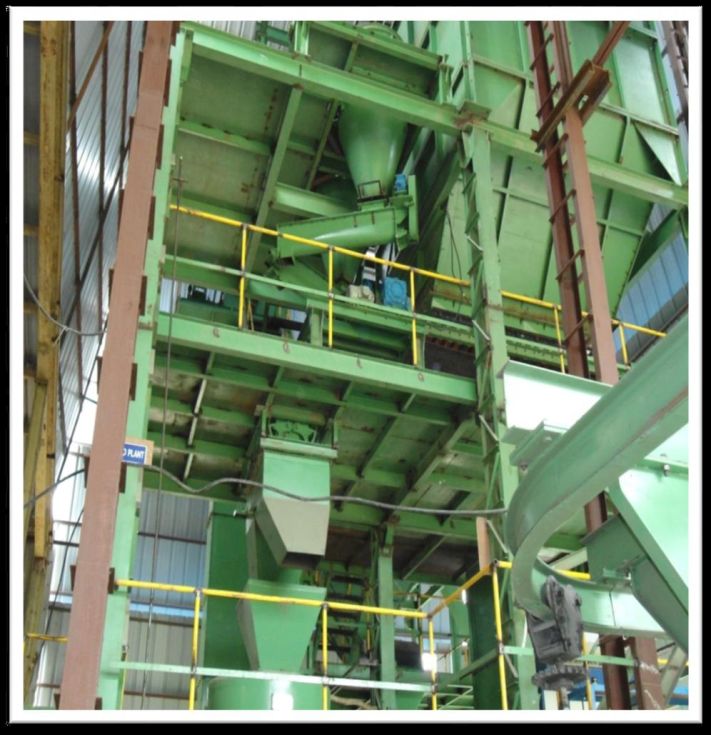

- Molding Section

- Arpa 300 Molding Machine With simultaneous squze joilt.

- Box Sizes – 16”X 20”X6” & 24”X29”X8”

- Loose Box Sizes – 16”X16”X4” , 18”X18”X4” , 22”X24”X6” & 20”X20”X6”

- Semi Atomized Sand plant with intensive sand mixer having capacity of 350kg, sand cooling system , poligonsieve , oms etc.

- 500kg knockout system .

- 300kg Sand muller for hand molding purpose.

- Fettling Section

- Table type shot blasting machine with two tables having capacity of 500kg per batch.

- 5Hp Table grander.

- 4’’ hand grander 1no.

- 12’’ hand grander 2no.

- 9’’ Shaft grander 2no.

- Core Section

- Shell core shooter.

- Sand mixer for Co2 as well as Nobake cores.

- Core hardness tester.

- Cold box core shooter Capacity 30kg

- Melting Section

- Indopower make 350kw 500kg capacity induction furnace with two pots.

- Overhead crane pouring system capacity of 750kgs.

- V – Smart make CE meter with temperature pyrometer.

Vision

- To Produce all types of complicated contours.

- To achieve 100% of installed capacity-400MT per month after six months.

- To Manufacture wide range of graded casting from 5 to 300 kgs.

- Value addition by supplying fully machined castings.

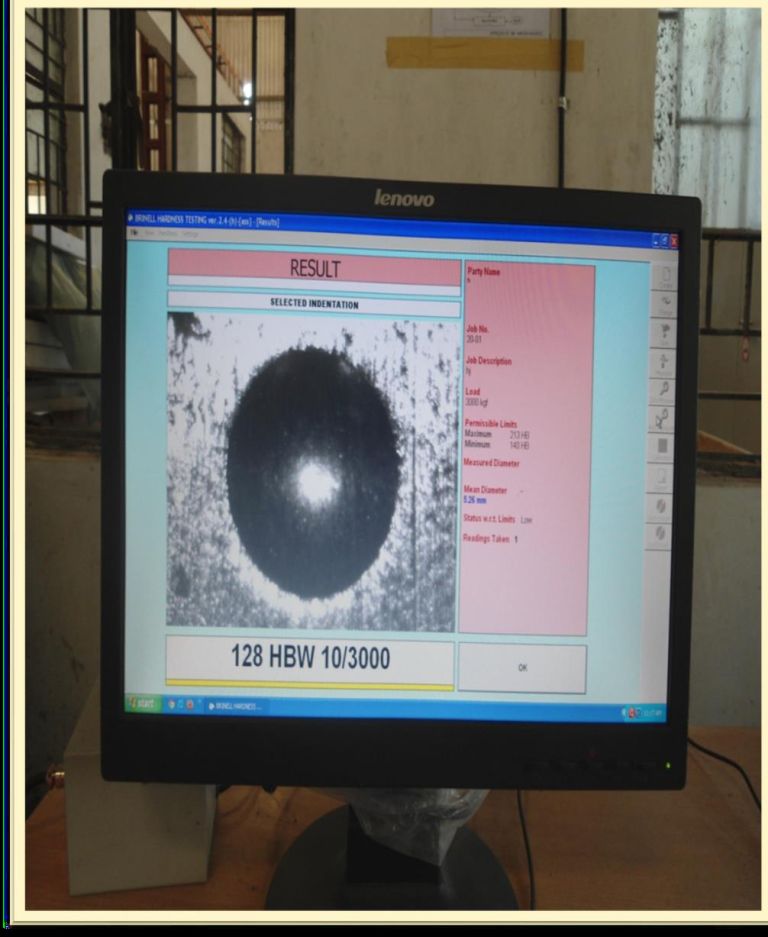

Quality Policy

- Ideal Industries Casting Division will deliver its quality products on time with new kanban quality system.

- Defect free & at a competitive price by adopting continual improvement method in our processes & products with customer satisfaction.

- To optimize the customer end rejection by introducing innovative foundry technology.

- Ideal Industries Casting Division will provide only core-competente products with good accknowledgement in given time.

Customer Base

- Crompton Greaves Ltd

- Premium Transmission Ltd

- Valvematics Eng. Pvt. Ltd

- Numerical Control Pvt.Ltd

- Shree Industries

- Vikram Industries

- Cummins Generator Technologies Ltd

- Ace Component

- Thyssenkrupp Ltd.

- Dynamic Presstress Nashik

- Anand Tecknow Aids Pune

Ideal Industries Casting Division deals in following

- Manufacturers of C.I. Casting

- SG Iron Casting

- Steel Casting

- Stainless Steel Casting

- High Alloys Casting

- Investment Casting

Address

F-37, MIDC, Ahmednagar

Contact

Phone : +91 241 2415471

Fax : +91 241 2779154

Email :ideal_ind@rediffmail.com