Indo Metaforge Pvt. Ltd.

Indo Metaforge Pvt. Ltd. is an ISO 9001:2008 certified, forging industry. Annual turnover of Rs. 15 crores. in 2021-22. The company is located at D-14, M.I.D.C., Ahilyanagar 414111 which has good infrastructure of roads, administrative office, laboratory, telecommunication & regular supply of electricity. Total area of factory is around 4050 Sq. meters.

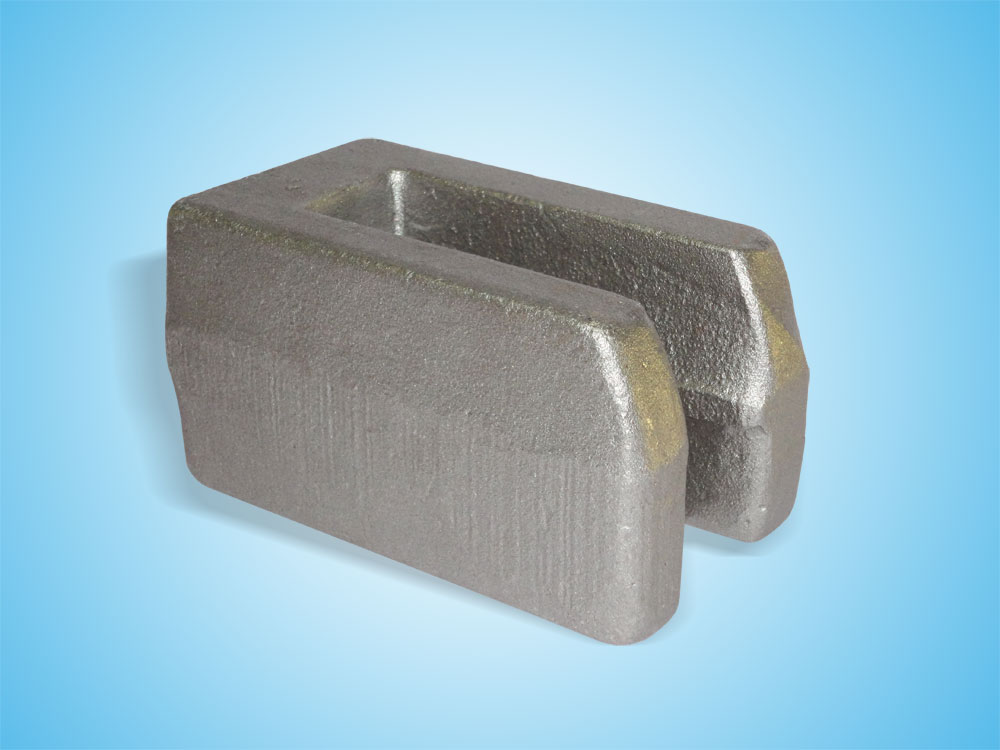

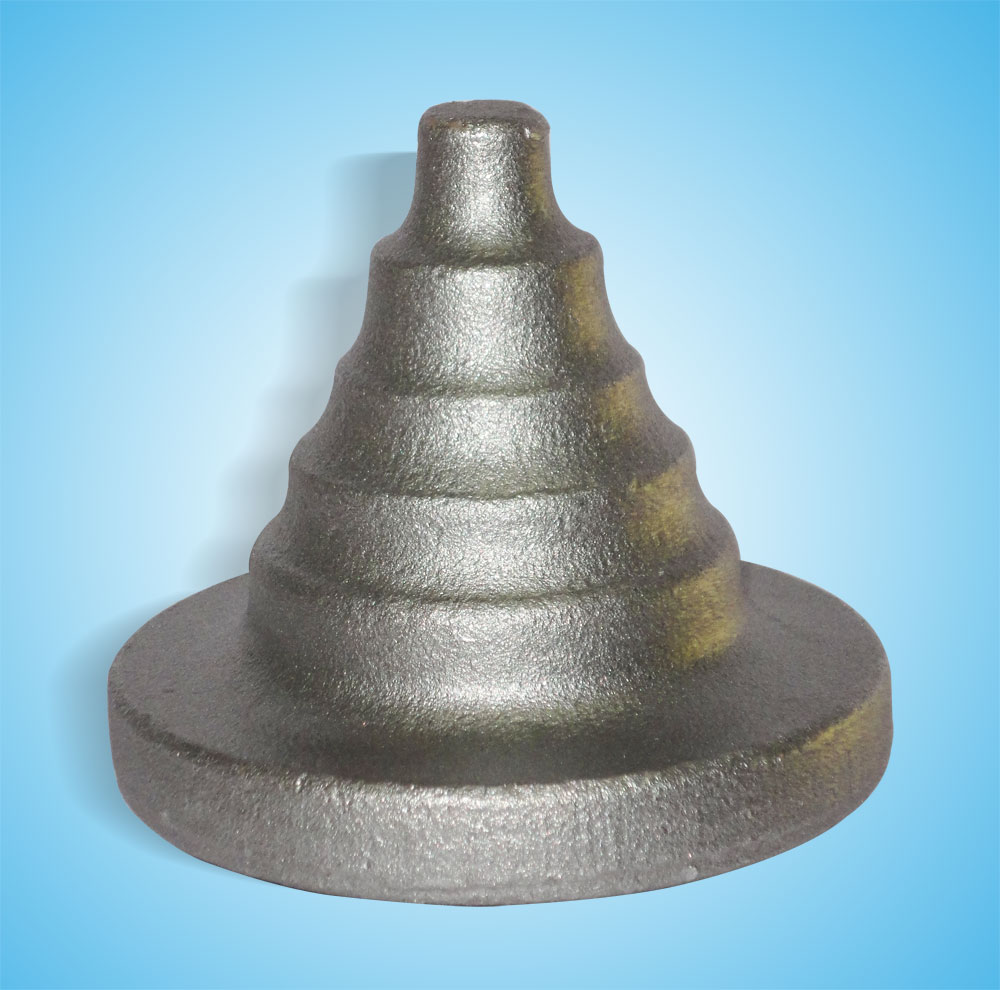

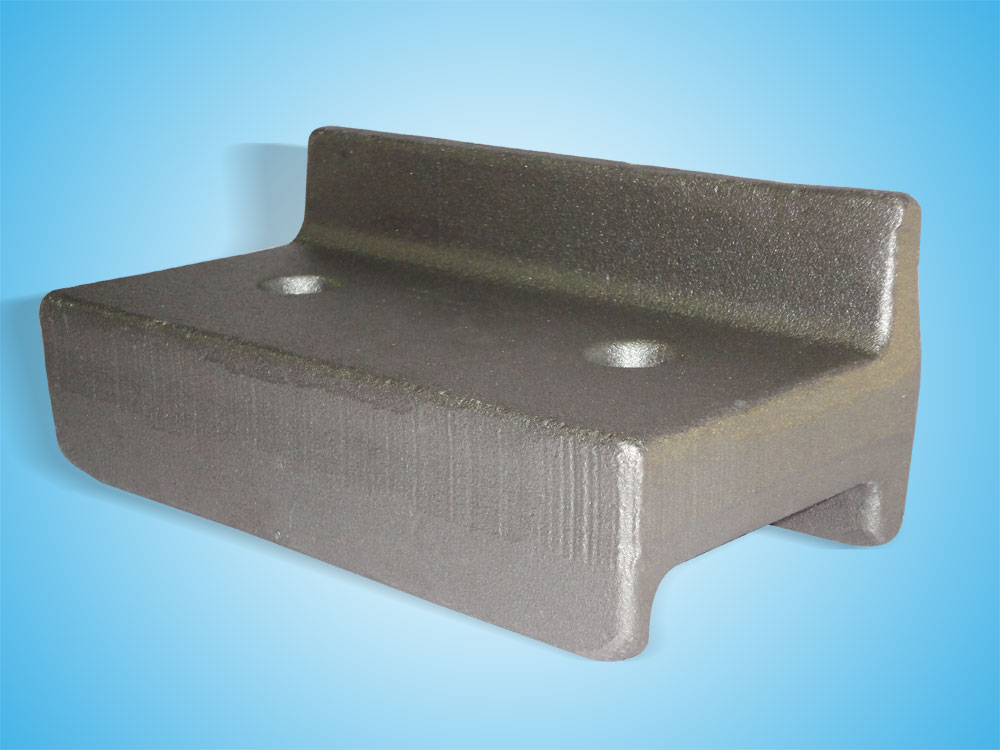

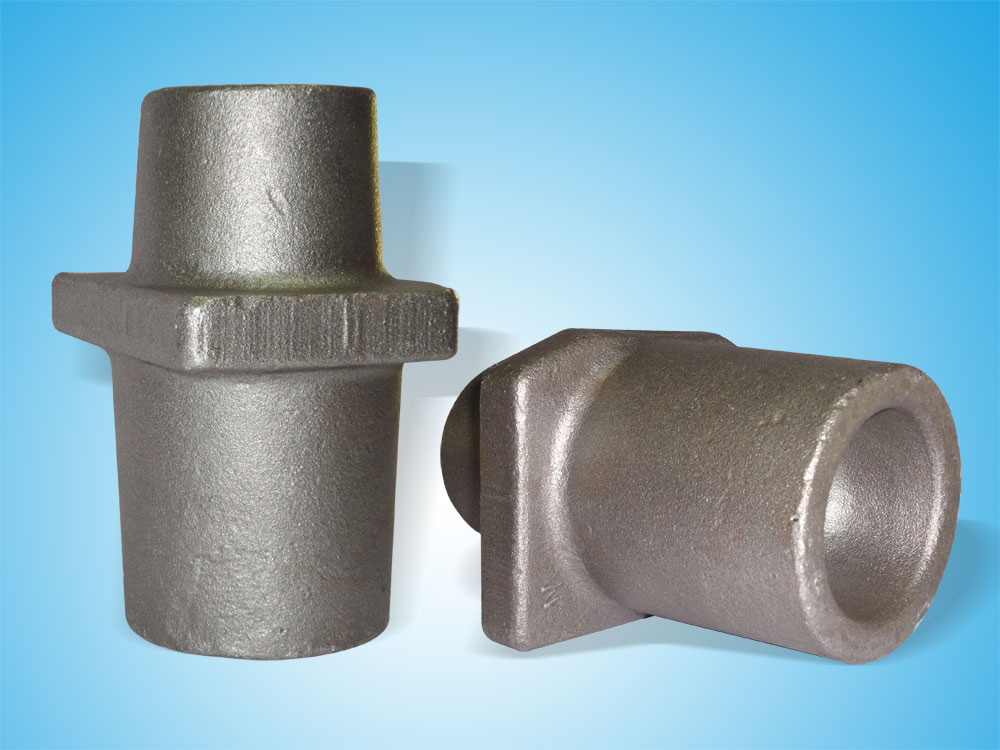

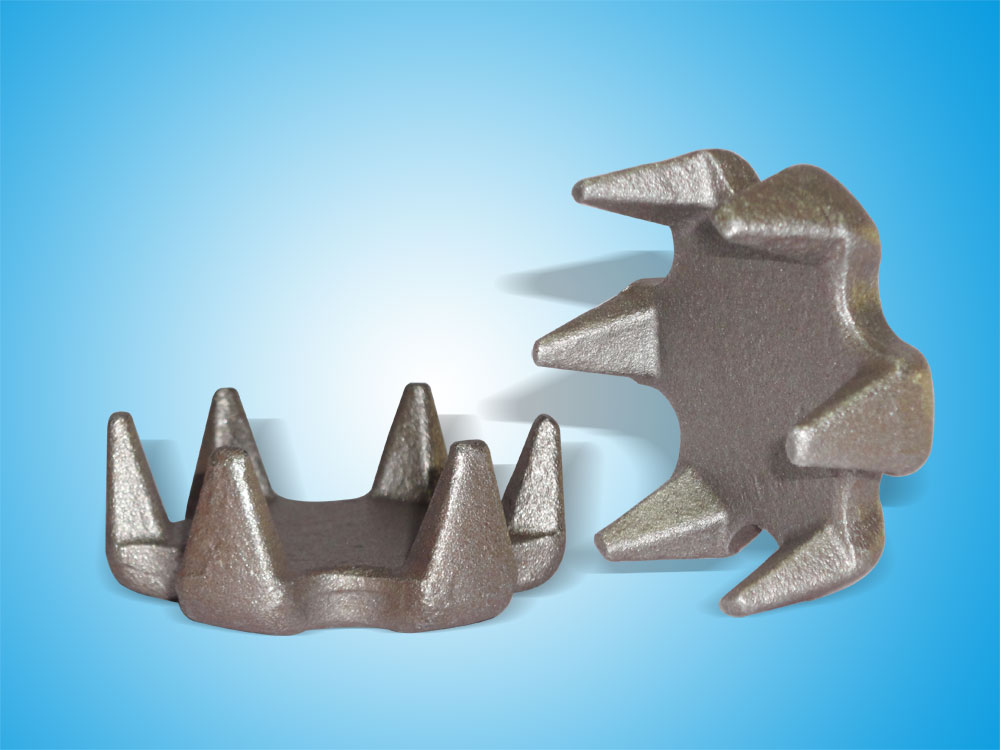

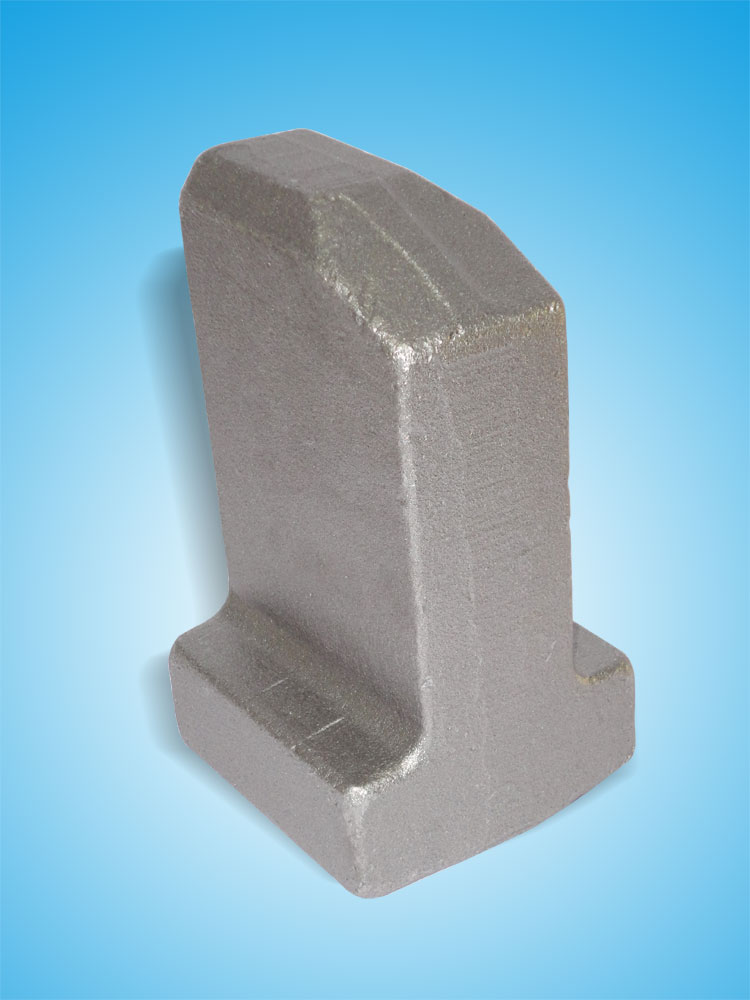

The company started its production in March 2006 & is engaged in the manufacture and supply of closed die steel forgings, as a reliable supplier of Quality Forgings to automobiles, tractors and other engineering companies. The components include Shafts, Levers, Yokes, Gears, Flanges, washers and Bearing Bushes etc. Weighing from 1 Kg To 17 Kg as per IS 3469 - 1974 Forging Tolerances.

Our Manufacturing Setup

Main production machinery comprises a 1.5 & 0.75 Ton Belt Drop Hammers with an annual capacity of 2000 Metric Tons forging of carbon and alloy steel, non-ferrous, special metals viz. Nickel Base alloys, Stainless steel etc, The supporting machinery consist of 200 Tons & 150 Tons trimming presses, oil fired furnaces for billet heating & heat treatment, bar shearing machine, Shot blasting machine etc.

Capacity

- Present capacity → 2000 MT

Forge Shop

| Sr. No. | Machinery | Qty | Make | Type | Capacity |

| 1 | Belt Drop Hammer – 1.5 Ton | 2 | Rajan Hammers | Friction Belt Drop | Forgings up to 7.5 Kg. |

| 2 | Belt Drop Hammer – 0.8 Ton | 2 | NSE- Massey | Friction Belt Drop | Forgings up to 3 Kg. |

| 3 | Trimming Power Press 200 Tons | 1 | Ravi Presses | Pillar | 200 Tons |

| 4 | Trimming Power Press 150 Tons | 1 | Aman power press | Pillar | 150 Tons |

| 5 | Induction Heating Furnace. 400 Kg/Hr with Temp. Indicators | 2 | Indeg | Box Type side Burner | Heating Capacity 400Kg/Hr |

| 6 | Induction Heating Furnace. 200 Kg/Hr with Temp. Indicators | 1 | Indeg | Box Type side Burner | Heating Capacity 200Kg/Hr |

| 7 | Air Compressor | 3 | Annest Iwata | Reciprocating | Max. Pressure 10Kg/cm2-45CFM |

| 8 | Welding Machine | 1 | Advani | Three Phase | 400 AMP |

Die Shop

| Sr. No. | Machinery | Qty | Make | Type | Capacity |

| 1 | VMC Machine | 1 | Bridgeport | Fanuc System 0- MATE |

Equipped with CAD/CAM Software |

| 2 | Vertical Milling Machine | 1 | HMT | FN 3V | Max 350 mm Height |

| 3 | Lathe 12’’ Center, Bed 6 feet | 2 | Ess Pee Ind. | With Semi Norton Gear | 200 Kgs. |

| 4 | Lathe 20” Centre, Bed 12 feet | 1 | Ess Pee Ind. | With Semi Norton Gear | 600Kgs |

| 5 | Lathe 12” Centre, Bed 5.5 feet | Sagar | With Semi Norton Gear | 200 Kgs. | |

| 6 | Pneumatic Air Grinder | 4 | C-P Tools | 3050 & 3051 | |

| 7 | Radial Drilling Machine | 1 | Energy | Radial, Fully Geared | 32mm |

| 8 | EDM (Spark Erosion Machine) | 1 | MMT | Hydraulic Ram | 60 Amps. With 800x500x500 |

| 9 | D.C. Welding Rectifier | 1 | Esab | 400 AMP | |

| 10 | Pedestal Grinder | 1 | Grind Tool | Wheel Ø 200 mm | |

| 11 | Electrical Hand Grinder | 1 | Dewalt | Angle Grinder | Wheel Ø100 & 175mm |

Cutting

| Sr. No. | Machinery | Qty | Make | Type | Capacity |

| 1 | Billet Shearing Machine | 1 | Shree Engineering Works | Mechanical | 100 mm Capacity |

| 2 | Bandsaw-10’’ | 2 | Laxmi Engg works | Semi automatic | 175 mm Capacity |

| 3 | Fully Automatic Band Saw Machine | 1 | Aditya | Automatic | 250 Ø |

Laboratory

| Sr. No. | Machinery & Testing Equipment | Qty | Make | Type | Capacity |

| 1 | Rockwell Hardness Machine | 1 | FTM Make | Model - OTRS | |

| 2 | Metal Spectroscope | 1 | SICO Feedback | Model 1500 | |

| 3 | Polishing Machine | 1 | Vardhan | Single Spindle | |

| 4 | Carbon & Sulphur Determinator | 1 | Abort Ind. | Combustion | |

| 5 | Muffle Furnace | 1 | Shital Scientific | 0 to 1000oC | |

| 6 | Laboratory Balance | 1 | Tapson | Single pan | 0.1 mg to 100 gm |

| 7 | Hot Plate | 1 | Steel Anal. | 3 KW | |

| 8 | Distilled Water Plant | 1 | Steel Anal. | 2 KW | 2 Lit/Hr. |

| 9 | Jominy Hardnability Test Equip. | 1 | Indigenous | ||

| 10 | Microscope | 1 | Vardhan | Inverted | 900 Magni |

Heat Treatment

| Sr. No. | Machinery & Testing Equipment | Qty | Make | Type | Capacity |

| 1 | Continues Normalizing Furnace | 1 | Ashwini Engg. | Automatic | 7 Tons per day |

| 2 | Hardness Testing Machine | 1 | FTM | TKB-3000 | 3000 Kg / 10 mm |

| 3 | Optical Hardness Testing Machine | 1 | FTM | TKB-3000 | 3000 Kg / 10 mm |

| 4 | Pedestal Grinder | 1 | Grind Tool | 2HP | Wheel Dia 250 MM |

Grinding & Finishing

| Sr. No. | Machinery | Qty | Make | Type | Capacity |

| 1 | Shot Blasting Machine | 1 | Peen-Blast | Rotoblast | 400 Kg / Charge |

| 2 | Pedestal Grinder | 2 | Grind Tool | Wheel Ø 300 mm | |

| 3 | Belt Grinder | 2 | Indigenous | 3 HP |

Inspection & Quality Control

| Sr. No. | Machinery & Testing Equipment | Qty | Make | Type | Capacity |

| 1 | Magnaflux M/c with Demagnetizer | 1 | Mayuresh | EMCO 457 55P | 2500A-15KAT |

| 2 | All Measuring instrument Includes surface plate, height gauges, Vernier calipers, radius gauges, V blocks, pistol calipers etc. | Mitutoyo |

Quality of Inputs

At IMF, the raw material required for any forgings are bought only from prime manufacturers in the country viz KSL, SAIL/VISP, ISSAL, SUNFLAG, AARTI STEEL, JSW STEEL etc. These prime manufacturers have been approved as Suppliers, based on our evaluation of their capability and quality systems. We do not compromise on QUALITY. A dedicated, trained and skilled workforce is the backbone of the Quality System.

Company’s real strength is in its:

- Producing forging as per customer specification & forging tolerances as per IS 3469:1974

- Ability to achieve International Quality Standards.

- Flexible, diligent and sincere team.

- Adequate manufacturing infrastructure.

- Ability to carry out continual improvement.

- Customer oriented services.

Our Esteemed Customer

- Premium Transmission Ltd, Chhatrapati Sambhajinagar (Group of Crompton Greaves)

- KSPG Automotive India Pvt. Ltd. Ahilyanagar

- Mahindra CIE, Chakan (Pune) & Rajkot

- Supreme Automech (I) Pvt. Ltd. Pondicherry

- Bhansali Trailers (I) Pvt. Ltd., Ahilyanagar

- IGL Pvt. Ltd., Chhatrapati Sambhajinagar

- LGB Ltd., Pondicherry

Address

Office : G-36, MIDC, Ahilyanagar

Contact

Mobile: Mr. Mahesh R. Indani +91 9881238402

Mobile: Mr. Tanmay M. Indani +91 7057718249

Email :mahesh.indani@indometaforge.in